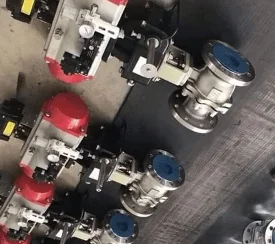

Pneumatic Actuated Valve

South American Valve is a popular Pneumatic Actuated Valve Manufacturer in Mexico. A pneumatic actuated valve is a type of valve that is operated by compressed air. The valve actuator is connected to the valve body and is designed to move the valve’s internal mechanism to control the flow of fluid through the valve. The pneumatic actuator can be either a piston actuator or a diaphragm actuator.

Piston actuators use compressed air to move a piston that is connected to the valve stem. The piston applies force to the valve stem, which moves the valve disc to regulate the flow of fluid through the valve. Piston actuators are often used in applications where high actuation force is required.

Diaphragm actuators use compressed air to move a diaphragm, which is connected to the valve stem. The diaphragm applies force to the valve stem, which moves the valve disc to regulate the flow of fluid through the valve. Diaphragm actuators are often used in applications where a compact design and low actuation force are required.

Advantages

Fast operation: Pneumatic actuated valves can respond quickly to changes in the control signal, making them ideal for applications where fast operation is required.

Simple design: Pneumatic actuated valves have a simple design and are easy to install, operate, and maintain.

Low cost: Pneumatic actuated valves are often less expensive than electric or hydraulic actuated valves, making them a cost-effective choice for many applications.

High reliability: Pneumatic actuated valves are known for their high reliability and durability, due to their simple design and the absence of electrical components.

Easy automation: Pneumatic actuated valves can be easily automated using programmable logic controllers (PLCs) or other control systems, allowing for remote operation and control.

Low power consumption: Pneumatic actuated valves require only a small amount of compressed air to operate, making them an energy-efficient choice.

Industries

Oil and gas: Pneumatic actuated valves are used in the oil and gas industry for flow control, shut-off, and safety applications.

Chemicals: Pneumatic actuated valves are used in the chemical industry to control the flow of various chemicals in production and processing applications.

Water and wastewater: Pneumatic actuated valves are used in the water and wastewater treatment industry for flow control, shut-off, and regulation of water treatment chemicals.

HVAC: Pneumatic actuated valves are used in heating, ventilation, and air conditioning (HVAC) systems to regulate the flow of air and fluids in commercial and industrial buildings.

Power generation: Pneumatic actuated valves are used in power generation facilities for flow control and shut-off applications in boilers, turbines, and other equipment.

Types

Ball valves: Ball valves are commonly used in pneumatic actuated applications due to their quick operation and simple design. They are ideal for applications where fast response times are required.

Butterfly valves: Butterfly valves are often used in pneumatic actuated applications where a large flow rate is required. They are less expensive than ball valves and have a simpler design, making them a popular choice in many industrial applications.

Globe valves: Globe valves are commonly used in pneumatic actuated applications where precise control of fluid flow is required. They have a linear flow characteristic and can be used to regulate the flow of liquids and gases.

Diaphragm valves: Diaphragm valves are often used in applications where contamination is a concern, as the diaphragm isolates the fluid flow from the valve body. They are ideal for applications where precise control is required, such as in the pharmaceutical and food and beverage industries.

Pinch valves: Pinch valves are used in applications where the fluid being controlled contains solids or abrasive materials. The valve body is made of an elastomeric sleeve that is pinched closed by a mechanism, preventing the solids or abrasive materials from damaging the valve.

Applications

Oil and gas: Pneumatic actuated valves are commonly used in the oil and gas industry for flow control, shut-off, and safety applications.

Chemicals: Pneumatic actuated valves are used in the chemical industry to control the flow of various chemicals in production and processing applications.

Water and wastewater: Pneumatic actuated valves are used in the water and wastewater treatment industry for flow control, shut-off, and regulation of water treatment chemicals.

Configuration of a Pneumatic Actuator:

Torque – 3 – 9000 nm

Operating pressure- 8 Bar

Port Connection-NPT1.4”

Mounting Base-ISO5211

Temperature–20°C – +80°C

Description

Material: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M, F55, F51, F53, Monel, Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

Class: 150-2500, PN6-PN450

Ends: Flanged, Socket weld, Butt weld, Lug, Wafer, Threaded.

Operations: Pneumatic Actuated

Pneumatic 3 Piece Flanged Ball Valve

Pneumatic 3 Way Flanged Ball Valve

Pneumatic Actuated 2 Piece Ball Valve

Pneumatic Actuated 2 Piece Flanged Ball Valve

Pneumatic Actuated 3 Piece Ball Valve

Pneumatic Actuated Butterfly Valve

Pneumatic Actuated Gate Valve

Pneumatic Actuated Valves

Pneumatic Actuated Butterfly Valve

Pneumatic Actuated Butterfly Valve

Pneumatic Actuated Knife Gate Valve

Pneumatic Actuated Ball Valve